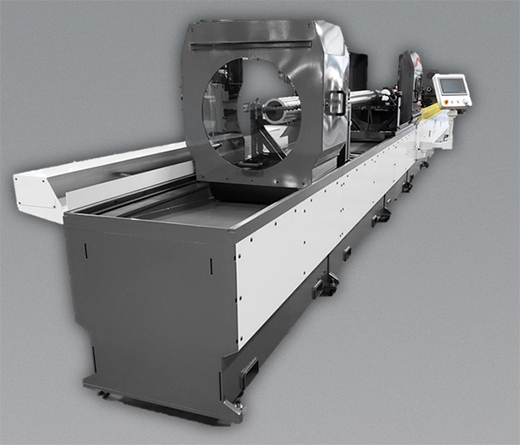

PowerHone Horizontal Honing Machines

OTW has revamped and rebranded its popular medium-duty OTW 1000 horizontal honing machine. The newly named PowerHone horizontal tube honing machine features full servo control and a redesigned user interface, Allen-Bradley controls and a new, modular platform that will improve equipment order lead times by 30%.

The PowerHone horizontal honing machine is offered with multiple fixturing and system options and is ideal for parts processed in the aerospace, defense, plastics and hydraulics industries.

- Automatic tool expansion with load sensing

- Universal part-holding fixtures

- Stationary driveshaft support

- 1.5” diameter hardened steel ways

- 2.0” diameter bayonet spindle

- Touch screen operator controls

- Auto dwell/short-stroke

- Part program storage

- Driveshaft indexing feature

- IIot ready, with full data capability

- Remote connectivity for online support and monitoring

- Collant filtration system

- Small bore processing options

- Large variety of abrasive honing stones

Honing Machine Specifications

| POWERHONE HORIZONTAL | |

|---|---|

| Medium Duty | |

| “Simple and Precise” | |

| Spindle Power (Max) | 20,0 kW |

| Drive Type | Servo |

| Stroke Power | 11,0 kW |

| Drive Type | Servo |

| Feed System | Linear, Servo |

| ID Capacity Min. (Rec.)* | 0.5” (12mm) |

| ID Capacity Max (Rec.)* | 22.0” (559mm) |

| OD Capacity* | 22.0” (559mm) |

| Optional Stroke Capacity | Up to 26' (8M) |

| Reciprocation Rate (Infinitely Variable) | 1 -100 FPM |

| Tooling Type | MD/MD Modular |

| (ref. OTW Tooling Catalog) | |

| Max Stock Removal** | 1.00 in3/min |

| (16,4 cm3/min) | |

| Typical Industries Served | Aerospace |

| Defense | |

| Plastics | |

| Hydraulics | |

| *Recommended based on typical application. Options available. **Based on recommended tooling using conventional abrasives in mild steel | |

See other OTW horizontal honing machine options:

- VersaHone – flexible-duty horizontal honing machine

- UltraHone Standard – heavy-duty horizontal honing machine

- UltraHone XL – ultra-heavy-duty horizontal honing machine

Contact an OTW honing specialist or call 419-281-3700 for assistance in choosing the right honing machine configuration for your applications.