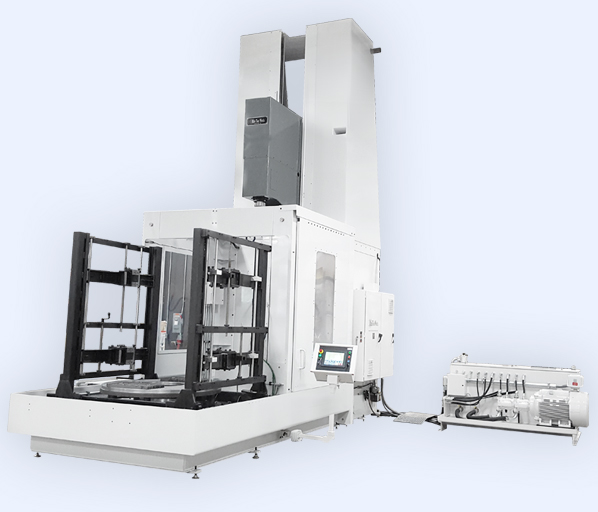

UltraHone XL Vertical Honing Machines

For the heaviest stock removal requirements and highest production volumes, OTW offers a hydraulic version of its UltraHone vertical honing machines.

The UltraHone XL, replacing the previously named OTW-V10, features upgraded Allen-Bradley controls for simplified use and more consistent results. This piece of honing equipment is ideally suited for the aerospace, automotive, defense, hydraulics and energy industries, with a bore size range from 1.5 inches to 24 inches and a stroke length up to 72 inches.

- Single- and two-stage tool expansion with load sensing

- Automatic size control options

- Median size control system

- Plug type setting

- Completely self-contained design

- Touch screen PLC operator controls

- Wide selection of fixturing options

- Coolant system/filtration options

- Coolant refrigeration options

- Single and dual expansion tooling options

- Variety of abrasive honing stones

Honing Machine Specifications

| ULTRAHONE VERTICAL | |

|---|---|

| Ultrahone-XL | |

| “Maximum Productivity” | |

| Spindle Power (Max) | 50.0 HP (37,3 kW) |

| Drive Type | Hydraulic |

| Stroke Power | 25.0 HP (18,6 kW) |

| Drive Type | Hydraulic |

| Feed System | Push, Hydraulic Linear, Servo |

| ID Capacity (Rec.)* | 1.5” (38mm) |

| ID Capacity (Max)* | 24.0” (610mm) |

| OD Capacity* | 26.0” (660mm) |

| Optional Stroke Capacity | Up to 72" (1829mm) |

| Reciprocation Rate (Infinitely Variable) | 10-100 FPM |

| Tooling Type | HD/HD Modular |

| (ref. OTW Tooling Catalog) | |

| Max Stock Removal** | 2.5 in3/min |

| (40,9 cm3/min) | |

| Typical Industries Served | Raw Materials |

| Defense | |

| Plastics | |

| Hydraulics | |

| Energy | |

| *Recommended based on typical application. Options available. **Based on recommended tooling using conventional abrasives in mild steel | |

See other OTW vertical honing machine options:

- VersaHone Vertical – flexible-duty honing machine

- PowerHone Vertical – medium-duty horizontal honing machine

- UltraHone Vertical Standard – heavy-duty honing machine

Contact an OTW honing specialist or call 419-281-3700 for assistance in choosing the right vertical honing machine configuration for your applications.